Cannabis vaporizer, despite being one of the most preferred cannabis consumption tools, still has some flaws. The workaround for this fragility becomes the responsibility of the cannabis vaporizer manufacturers. One of the prevalent issues that we can encounter with cannabis vaporizer usage is leaking. How does this problem come to the surface in the first place? Let’s get down to the list of possibilities.

#1 Airflow inside the cannabis oil tank

Generally, conventional cartridge companies will pre-fill their products before sending them to retail shops. During this filling process, the cannabis vaporizer’s oil tank is constantly exposed to free air, creating airflow within the chamber. The technician must fill and cap the devices as soon as possible to prevent cannabis oil oxidation, which leads to the degradation of the product quality, and to prevent the leaking phenomenon caused by excessive airflow that enters the oil tank. When the cannabis vaporizer has been used for a certain period, the ceramic heating core will gradually reduce its ability to radiate enough heat that transforms the cannabis oil into vapor. Meanwhile, the cannabis oil will keep flowing into the ceramic’s microporous structure without being adequately absorbed and vaporized. Due to atmospheric pressure, the existing airflow and aged ceramic will eventually cause the leftover cannabis oil to leak through air inlet holes in its closest proximity.

#2 Improper filling process

Cannabis vape leaking is closely related to the amount of cannabis oil inside the oil tank. When the operators or cannabis vapers overfill the oil tank or overheat the cannabis oil, the cannabis vape device will likely leak throughout the usage. Unintentional spill by the operator during the oil filling process causes oil waste and an increase in processing costs. Overheating the cannabis concentrate may lead to the total volume of cannabis oil to increase with the oil temperature lowering gradually and result in oil leaks from the oil injection hole. Shipment to the client will also be delayed because extra measures must be taken to ensure no more leakage will happen. In the worst-case scenario, vape leaking may affect product reputation and company brand image, making them inferior to other companies. It is suggested to leave part of the top portion of the tank empty and conduct filling process slowly to avoid flooding the tank.

#3 Faulty capping procedure

The capping process requires the operators to properly seal the cannabis vaporizer. When the capping utilizes the press system, the operators should be mindful of the force they apply. Pressing the cap too hard may damage the O-Ring seal that is supposed to establish a watertight condition in a cannabis vape device. The same also applies to the screw cap. Another tip for cannabis vaporizers that wield cannabis oil with relatively thicker consistency should allow the oil to settle at the bottom before commencing with the capping process.

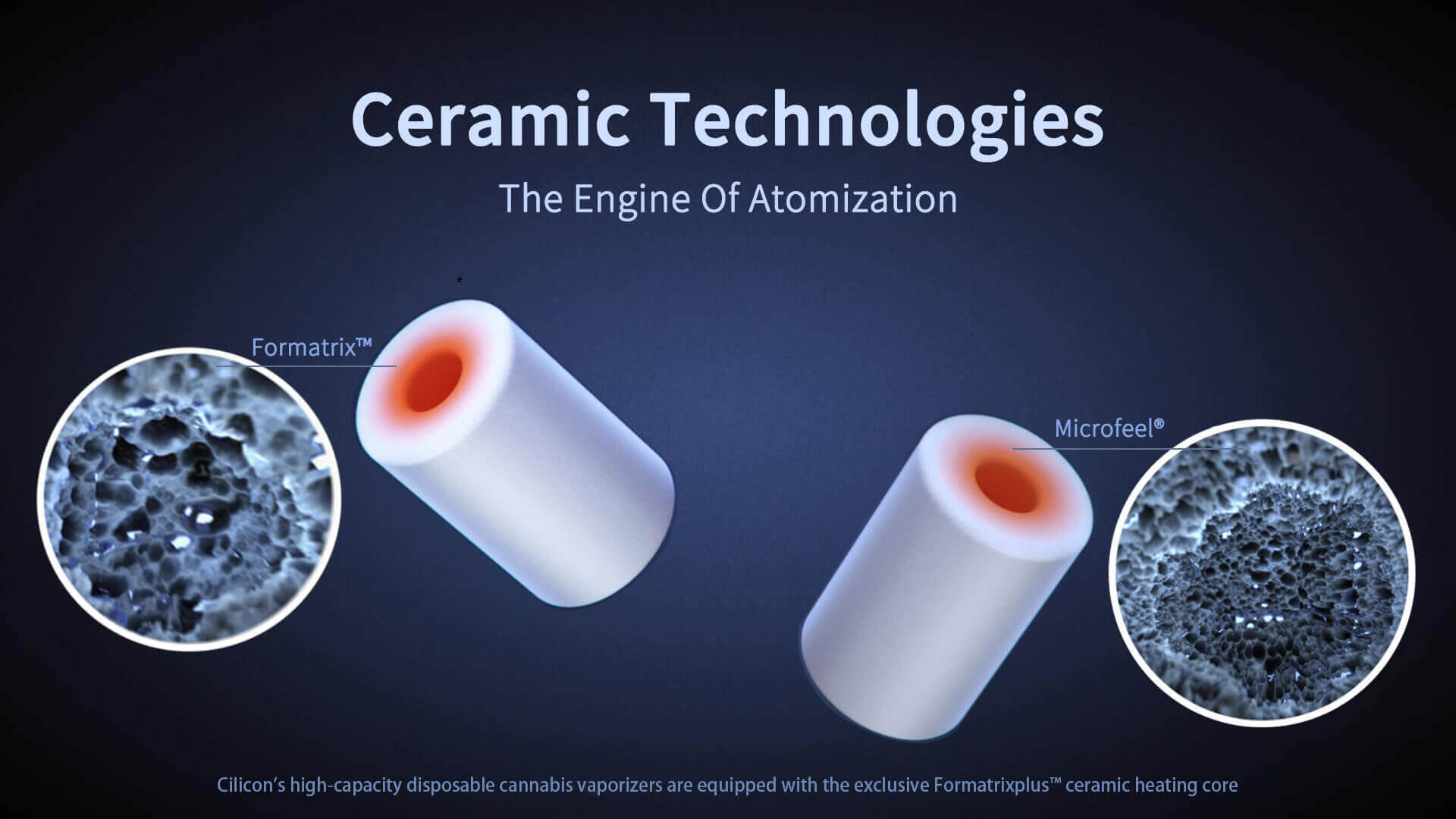

#4 Mismatching ceramic heating core

Choosing the right cannabis vaporizer with a suitable heating core is advisable. Most vaporizer heating core is made of ceramic nowadays. In light of matching different cannabis oil, an adaptive high-capacity ceramic heating core with a proper diameter of micropore is needed. Too big diameter of micropore causes a lower ability of the heating core to lock cannabis oil, and low-quality ceramic may also lead to the absorptive ability of the ceramic declines. Both two traits above are the root of leaking caused by an improper ceramic applied. Therefore, in order to get a preferred ceramic, make sure to find a professional cannabis vaporizer supplier to discuss and choose a well-designed microporous structure with high adaptability.

#5 Incompatible Oil Inlet Hole

An oil inlet hole is a cavity that is designed for the oil tank at the bottom of the central tube. It is used for letting the oil flow into the heating core. Despite its size, this tiny hole becomes a crucial part of the devices that every vaporizer company should emphasize. As there are many types of oil and viscosity levels being sold on the market, companies should choose the correct hole size to ensure its compatibility.As the customers, we also need to observe this tiny hole very carefully. As stated, the oil inlet does not come with a universal size. There are 4 to 5 different types of oil inlets in the current market, and not all of them are always compatible with the viscosity of the oil sold. Choosing the right size for your use may not only help with your leaking issue but also affect the enjoyment of taking that dose of cannabis oil.

Cilicon’s Ultimate Breakthrough in Minimizing Cannabis Vape Leaking Risk

This oil leakage issue continually becomes a major turn-off for the cannabis vapers as they would not be able to maximize their valuable cannabis oil usage. While leaking is inevitable phenomenon in a cannabis vape device, the foremost step a cannabis vaporizer manufacturer can take is to find a way to minimize the risk as much as possible through a technological breakthrough. Acknowledging this necessity, Cilicon’s R&D team has devised a brilliant solution to suppress the leaking risk at its most vulnerable time. This phenomenal breakthrough is called the oil isolation technology. So, how does Cilicon’s Oil Isolation™ technology work?

Refer to: How the Oil-Isolation Technology Solves 99% of the Oil Leaking Problem?

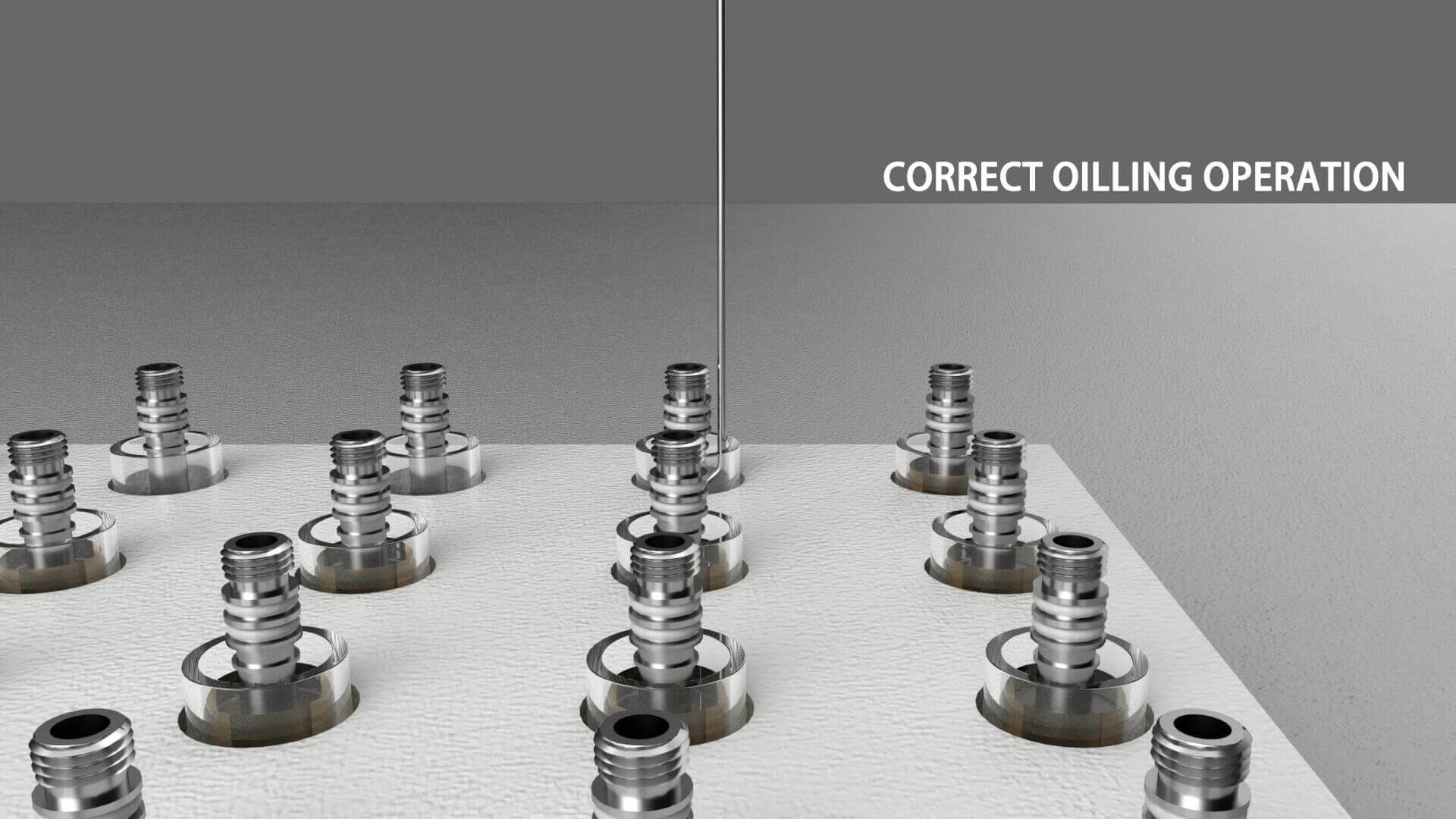

Cilicon identifies that the risk of vape leaking peaks during the cannabis oil filling process. Upon this realization, we invented the Oil Isolation™ Technology that separates the cannabis vaporizer’s oil inlet hole from the oil tank. While the cannabis vaporizer’s oil inlet hole is generally in direct contact with the oil tank, the injected cannabis oil may also leak through any existing opening through oil inlet hole such as the air inlet holes at the bottom of the oil tank. Cilicon’s oil isolation technology has successfully burned this bridge by omitting the contact between oil inlet hole and cannabis oil during oil filling process from which the cannabis oil leaks from oil inlet hole and ceramic heating core.

After the oil-filing process is completed, the operators will only need to push the metal holder and mouthpiece simultaneously during the mouthpiece capping process. The cannabis oil inlet hole will appear through the silicone seal at the bottom of the central tube into the cannabis oil tank. This process allows the cannabis oil to establish contact with the ceramic heating core only when the cannabis vape device is sealed off and avoids any cannabis oil leak out from the oil tank during the resting time.

Now that we understand how this top-notch technology benefits the cannabis vapers, we come to the question of how does it help a cannabis vaporizer business to thrive? First, the valuable resting time extension between the capping and cannabis oil filling processes has granted the assembly operators increased productivity. The conventional technology generally only provides them 3 to 5 minutes of resting before the cannabis oil leaks. In the lengthier downtime that the Oil Isolation™ Technology offers, the assemblers can fill more cannabis vaporizer’s oil tanks before the next capping cycle. Not to mention, this Oil Isolation™ Technology also gives less room for faulty operations to prevent from injecting cannabis oil to the wrong injection hole. Finally, the enhanced number of perfect assemblies at a time means that the cannabis vaporizer business can cut labor costs.

Cilicon’s cannabis vape devices also utilize a special ceramic heating core that can withstand high-temperature dissolution of up to 1,200°C. In addition, it has undergone more than 20,000 tests to prove its vaporizing performance. Combined with the oil isolation technology, say no more to the cannabis vape leaking problem! Cilicon ultimately provides an otherworldly cannabis vaping experience for the cannabis vapers and maximizes productivity for our cannabis vaporizer business partners.