Various ceramic heating elements are available in the market, which generally consist of a microporous ceramic paired with a heating coil. Most clients focus solely on its vaporizing performance based on the manufacturer’s recommendation while disregarding the essence of consumer safety.

Factually, ceramic has long been regarded as a safe material choice that can withstand high temperatures of up to 1,000°C, which is suitable for a cannabis vaporizer heating component. Why has this characteristic become essential? Many people alternate to cannabis vape devices to seek a safer method to consume cannabis. They usually originated from utilizing pre-rolled cannabis as their daily driver, which may escalate health risks like chronic pulmonary illnesses or respiratory problems due to its carcinogenic byproducts from the combustion process.

Despite the evident strength of ceramic as a heating conductor material, most customers still need the reassurance of the actual safety qualifications before deciding on a manufacturing partner. In this article, Cilicon® aims to dive deeper into the qualifying components of a ceramic heating element, including the raw material selections, added additives, and production processes, to establish a reassuring trading experience between cannabis vaporizer brands and consumers.

Raw Material

A premium ceramic heating conductor comprises various materials that can form highly strong and stable characteristics. Alumina and Silicon Dioxide are the most common materials that can facilitate this desired quality.

Alumina is extremely rigid, resistant to heat, acid, and alkali, and has highly chemical stability. Moreover, its high thermal conductivity allows a consistent heat distribution to eliminate the undesired burnt taste due to uneven heating of the cannabis oil. On the other hand, Silicon Dioxide material has less thermal conductivity but can deliver an efficient and explosive vaporizing performance.

More importantly, Alumina and Silicon Dioxide do not contain heavy metals or other toxic substances and comply with the RoHS and FDA standards. Incorporating these two components will create an enduring ceramic heating element that can stand the test of time.

Additives

To achieve the microporous attribute, the manufacturers have to add pore-forming agents into the ceramic material. One of the finest pore-forming agents is wax, which has a low-melting temperature, allowing it to be completely burned off during the sintering process. Wax is also scientifically proven safe as it does not produce harmful substances that may latch onto the ceramic surface even at a high temperature.

Once the sintering process is completed, the ceramic heating conductor will possess a microporous configuration. The factors that make one ceramic different from another are the size and amount of its micropores determined by the mix ratio of raw materials and pore-forming agents that undergo the sintering steps. The differences in micropore structure will affect how a ceramic heating element can deliver the genuine taste of cannabis, eventually altering the cannabis vaping experience for consumers.

In terms of safety, inappropriate sintering processes, such as adding additional toner into the mix, will cause harmful substances to be inhaled by consumers. Some toner ingredients, like cobaltous oxide, can form a black appearance and produce cobalt toxins that pose numerous health risks, including mental malaise, diarrhea, bronchial asthma, and cancers. On Oct 27th. 2017, the IARC (International Agency for Research on Cancer) of the World Health Organization has even included cobalt and its compounds in the 2B group of the carcinogen list.

Production Process

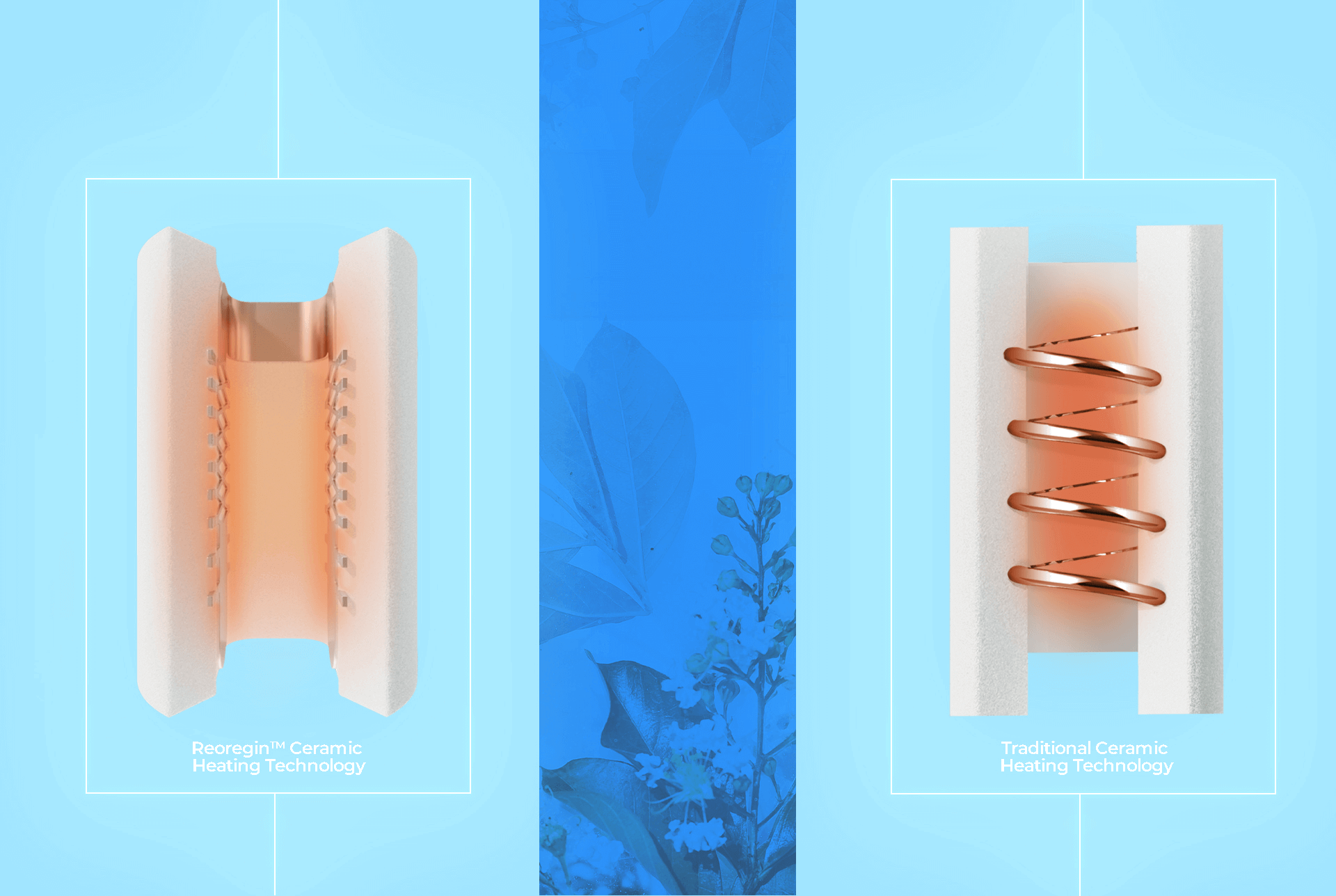

The production approaches of a ceramic heating element are generally divided into pre-welding and post-welding types. In the pre-welding method, the metal heating coil is initially welded into the ceramic before it goes through the sintering process. As a result, the metal may oxidize under high temperatures and produce harmful substances that can fall off the ceramic surface. Meanwhile, the post-welding technique is preferred as the sintering process is done before the welding step, ensuring that the heating coil remains intact, retains its original color, and does not produce hazardous ingredients during the whole process.

Cilicon’s Commitment to Ensure Consumer Safety

Cilicon’s R&D team has developed the innovative ReoreginTM ceramic heating technology to ensure maximum consumer safety by incorporating natural raw materials and automated production processes. Our choice of raw materials falls into high-grade kieselguhr and quartz without adding toner additives. We plan to maintain the natural characteristics of our ceramic heating element to achieve a natural and flavorful taste of cannabis without jeopardizing consumers’ safety.

The ReoreginTM technology implements the highly secure post-welding production process to ensure a reliable metal heating coil that can deliver a consistent taste and safe cannabis vaping experience. The actual production steps after the sintering process have been fully automated to prevent human intervention, translating into a swift and more sanitary ceramic heating element production process.