The cannabis vaporizer industry gets crowded as more states allow cannabis distribution. While it may seem like a rising opportunity, it also means that cannabis vape businesses must go above and beyond to become top-of-mind. The initial step you can take is to partner with credible suppliers that value quality in material choices and production processes.

One of the most crucial cannabis vaporizer manufacturing processes is the oil filling process. During production, the worker should strictly follow the oil filling instruction that provided by the vaporizer supplier. And the oil filling manufacturer is required to ensure that the cannabis oil inside the cannabis vape cartridges is in superb condition when distributed. Most importantly, the process must be done speedily or follow a fixed filling cycle to avoid cannabis oil oxidation, spit-back or oil leaking.

A scientific oil filling process should be efficient to maximize the production capacity. Some manufacturers still stand with the fully-manual cannabis oil filling method, which relies heavily on labor investment. While thinking that hiring low-wage workers are more beneficial, the built-up labor costs will eventually skyrocket as demand rises.

Not to mention, a faulty and decelerating process becomes inevitable as everything is done by hand. For instance, there are three holes on the silicone plug at the top of oil chamber, workers may mistakenly inject the oil into to the central post hole which is for transmitting the cannabis vapor from the heating core. Human labors also tend to be inconsistent due to fatigue from repetitive tasks. You may have risked overfilling your cannabis oil cartridges which can cause cannabis vaporizers to leak, ultimately jeopardizing your reputation in front of your customers.

The superior alternative to the manual-filling method is entrusting the tasks to an automated cannabis oil filling machine. So, how can this machinery help you fulfill your customer’s demand on time? Now, let’s dive deep into some advantages of investing in an automated cannabis oil filling machine!

#1 Achieve long-term cost-effectiveness

We cannot deny that a cannabis oil filling machine may not be the most pocket-friendly investment at first glance. However, while the upfront cost is relatively high, you can expect the return to happen quicker than you imagine as your production capacity increases.

An automated cannabis oil filling machine eliminates human errors and labor costs as it has high precision and only requires little to no machine operators, as most cannabis oil filling machines are made user-friendly. Combined with Cilicon Oil Isolation™ Technology, it will you’re your cannabis vaporizer lasts longer and have less possibility of oil leaking issue. Therefore, you can rest assured that you do not have to deal with cost-adding defective products as often anymore!

#2 Get your precise dose

You can find different cannabis oil filling machines from numerous brands that can handle liquid in various viscosities. Despite your selection, the essential advice is to go for a customized oil filling machine suitable for the cannabis oil of your choosing. This customized option aims to match your exact ratio and parameters so that you can deliver a consistent dose to each cannabis vaporizer you produce. Worry not, as these custom filling machines are still affordable and accessible!

#3 Achieve cleaner production with the appropriate setup

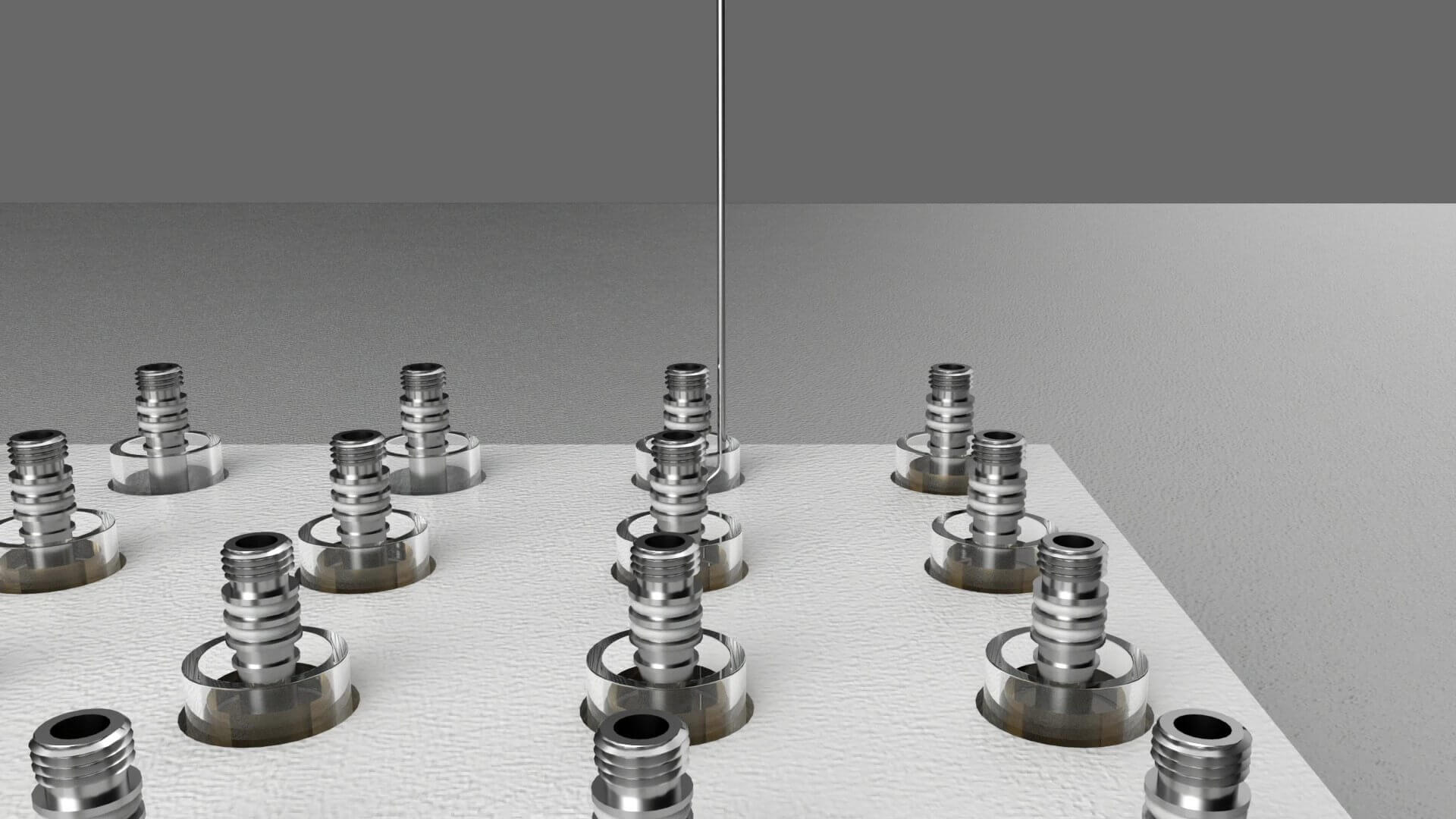

As cannabis vaporizer produces vapor that the users directly inhale, the hygienic aspect becomes indispensable. By selecting the suitable material for constructing your cannabis oil filling machine, you will prevent the risk of heavy metal precipitation that often happens when substandard material is being used. One of the materials that we recommend is 316L stainless steel. The “L” in this stainless steel variant stands for low carbon content, which indicates that it is a perfect option for the cannabis oil filling machine components directly in touch with the cannabis oil. The fun fact is that our cannabis vaporizer’s central post is also made of 316L stainless steel, and we have also ensured that it passed the heavy metal testing!

#4 Optimizations are possible to reach higher efficiency

If you already invest in cannabis oil filling machines, the next step is fully utilizing them through optimization to experience higher production efficiency. The initial phase of the optimization process is to analyze your production data. By having a quantifiable measurement, you can accurately walk through the cannabis oil filling process and witness where it’s lacking. For instance, if you discover that your cannabis oil is dripping out of the mouthpiece and creating a mess, you can optimize by installing a drip tray so that you will have squeaky clean cartridges! There are plenty of optimization options to improve your production process. Remember to involve your cannabis oil filling machine suppliers for a quick fix!

Cilicon’s patented technology can make your cannabis vape cartridge filling process more seamless and cost-effective.

Cilicon’s more than a decade of experience in the cannabis vaporizer industry has enriched us with the necessary insights to develop a technology that can help our clients triumph. Understanding how the filling process can be a nuisance sometimes, Cilicon introduces a patented technological breakthrough called the Oil Isolation™ Technology.

This top-notch invention separates the cannabis vaporizer’s oil inlet hole (or ceramic heating core) from the oil tank before the capping process. By moving the cannabis vaporizer’s oil inlet hole away from the oil tank, we have omitted the opening from which the cannabis oil may leak. Only after the cannabis oil filing process is completed will the operators push the metal holder and mouthpiece simultaneously during the mouthpiece capping process. The cannabis oil inlet hole will appear through the silicone seal at the bottom of the central post into the cannabis oil tank.

This process allows the cannabis oil to establish contact with the ceramic heating core after the cannabis vape device is sealed off and avoid any cannabis oil gurgling out from the oil tank during the filling time. Thereby, we have managed to resolve the cannabis vaporizer’s oil leaking issue at the root.

The way that the Oil Isolation™ Technology prevents leakage will eventually lead to a lower production cost due to the minimum amount of cannabis oil waste. At the same time, your capping operators will also experience a longer resting time between the cannabis vaporizer filling and capping process, ultimately enhancing filling accuracy.

For your end customers, the Oil Isolation™ Technology will help reduce airflow and stabilize the air pressure inside their cannabis vaporizer’s oil tank. As a result, the possibility of cannabis oil oxidation is suppressed to the minimum, preserving the cannabis oil at its finest quality.

Combining an automated cannabis oil filling machine and our Oil Isolation™ Technology will help you achieve sky-high production efficiency. Fulfilling your customer’s demand can now be a speedy and cost-effective journey!